Advanced Lithium Battery Module Solutions

Robur delivers high-performance LiFePO₄ battery modules designed for industrial, mobility, and energy-storage applications.

Our in-house engineering team optimizes cell matching, mechanical structure, BMS protection, and thermal management to ensure stable output and long cycle life.

Through strict testing and controlled manufacturing, our modules help OEM customers achieve safer systems, higher reliability, and smoother integration into their equipment.

Wide-Tab A-Grade Prismatic Cells

Robur uses brand-new A-grade prismatic cells, featuring wide tabs, aluminum shell construction, and laser-welded large contact surfaces. These cells deliver exceptionally low internal resistance, outstanding consistency, and long cycle life—ensuring stable performance even in demanding fleet environments.

Longer cycle life: 3500–6000 cycles

Higher discharge capability with lower heat generation

Better batch consistency → smoother system integration

Wide-tab structure reduces loss during high-current output

Cell-to-Cell Fire-Resistance Barrier for Maximum Safety

Robur’s modules integrate a dedicated cell-to-cell thermal isolation layer that provides outstanding flame-resistance and prevents heat propagation in extreme conditions. The barrier withstands thermal shock exceeding 1400°C, ensuring that even if a single cell experiences abnormal heating, the temperature is contained and does not spread to adjacent cells. This automotive-grade safety design greatly enhances the pack’s resilience, improves system-level protection, and provides a critical safeguard for high-power applications.

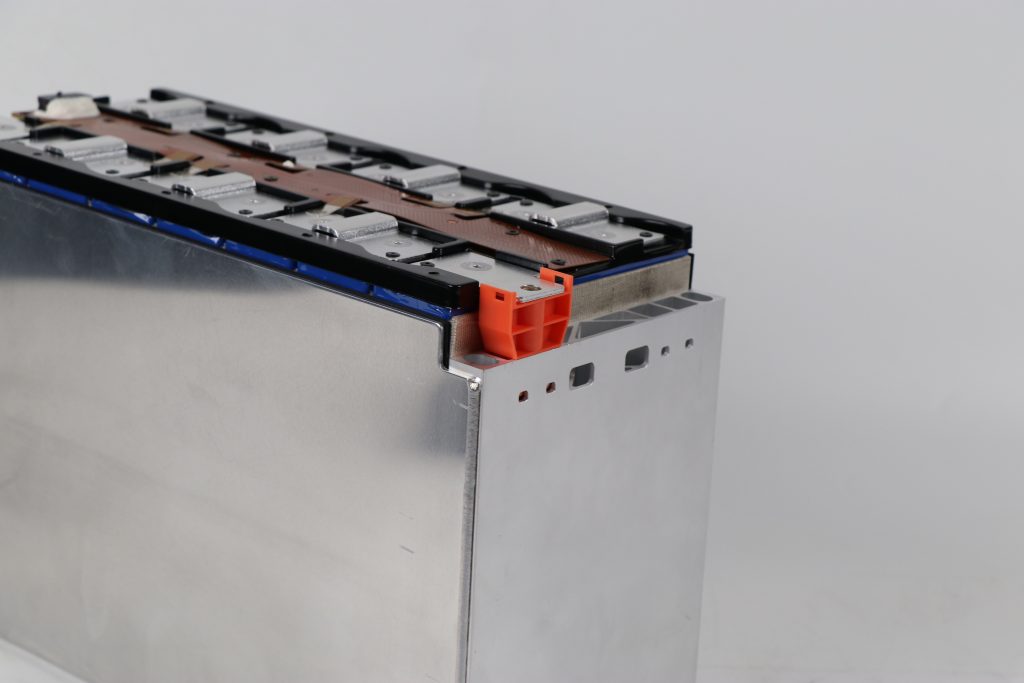

High-stability aluminum profile frame

The module adopts a high-rigidity aluminum extrusion frame that provides far greater structural strength and vibration resistance than traditional sheet-metal housings. Its excellent thermal conductivity accelerates heat dissipation, helping the cells maintain stable performance under continuous high-load operation. The precise dimensional accuracy of the aluminum structure ensures high assembly tolerances, prevents long-term deformation, swelling, or compression loss, and protects the internal components throughout the battery’s service life. This results in a more reliable, durable, and maintenance-friendly system for demanding applications.

Precision Compression System for Longer Cycle Life

Robur’s aluminum-extrusion compression frame is engineered as a full pre-tensioning system, not just a protective shell. Compared with folded sheet-metal housings, the high-rigidity extrusion provides uniform pressure distribution across every cell, preventing swelling, micro-gaps, and long-term structural drift. This stable compression environment minimizes contact-resistance variation, reduces heat generation during high-current operation, and protects the cell’s internal structure from vibration and mechanical fatigue. Across thousands of charge–discharge cycles, the frame maintains dimensional stability, preserves busbar alignment, and ensures the entire module continues to operate safely, efficiently, and consistently throughout its service life.

Automotive-Grade FPC Sensing and Laser-Welded Busbar System

Robur adopts an automotive-grade sensing architecture: FPC flexible circuits for precise cell-level sampling, paired with dual-layer aluminum busbars welded through high-precision laser processes. This ensures extremely low impedance, reliable large-current delivery, and long-term structural robustness.

Continuous high-current support: 150A–300A

Extremely low contact resistance → lower heat & higher efficiency

Compact, vibration-resistant structure

More accurate BMS data due to stable sampling paths

Standardized Module Platform for Fast Integration

Robur’s standardized module architecture enables rapid configuration into 24V, 48V, 72V, and higher-voltage systems, significantly improving R&D efficiency and shortening development cycles. With unified mechanical dimensions, consistent cell layout, and standardized electrical interfaces, system scaling and customization become easier and more predictable. This platformized approach also enhances batch-to-batch consistency, accelerates certification readiness (UN38.3, CE, IEC, UL), and reduces long-term engineering and maintenance costs for OEMs and fleet operators.

System-Level Consistency for Long-Term Reliability

Robur’s modules are engineered to deliver system-level consistency — the single most important factor affecting battery safety, lifespan, and high-current performance. Consistency begins with the foundation of every module: brand-new A-grade cells, followed by secondary screening to ensure matched impedance, capacity, and voltage. The cells are then stabilized through an aluminum compression structure that prevents swelling and keeps internal resistance from drifting over time.

At the electrical level, laser-welded busbars provide uniform low-impedance current paths, while automotive-grade FPC sensing ensures accurate, stable cell-level monitoring without the errors common in wire-harness systems. Combined with a standardized mechanical layout and tightly controlled assembly tolerances, every Robur module behaves the same from batch to batch — a critical requirement for fleets and OEM applications.

Superior consistency translates directly into benefits customers can feel: more predictable performance, higher safety margins, slower degradation, and reliable high-power output even after years of cycling. For operators and manufacturers, this means fewer failures, less downtime, reduced replacement cost, and confidence that every Robur module performs exactly as engineered.