Ampere-hour (Ah) is one of the most commonly used units for describing battery capacity. Simply put, it indicates how much current a battery can discharge and for how long it can sustain that discharge. Its definition is straightforward:

Ah = Discharge Current (A) × Discharge Time (hours)

For example, a 100Ah battery, under the assumption of constant voltage, can theoretically operate at a discharge current of 5 amperes for 20 hours (5 × 20 = 100), or at 10 amperes for 10 hours (10 × 10 = 100). As the discharge current increases, the discharge time becomes shorter.

Because of this relationship, Ah is widely used in practical applications as a basic reference for estimating battery runtime. Within the same voltage system (for example, 48V), and under similar conditions, a higher Ah rating generally indicates longer operating time.

Key Battery Parameters Commonly Associated with Ah

To correctly understand ampere-hours (Ah), it is first necessary to understand several battery parameters that are frequently mentioned alongside it: voltage, current, energy, and power.

Among these parameters, Ah has a very specific physical meaning. From a physics perspective, Ah primarily describes the total amount of electric charge stored in a battery—in other words, how many electrons the battery can deliver over a period of time. It is an independent parameter, and by definition, it does not directly depend on voltage, power, or energy.

A Simple Analogy for Better Understanding

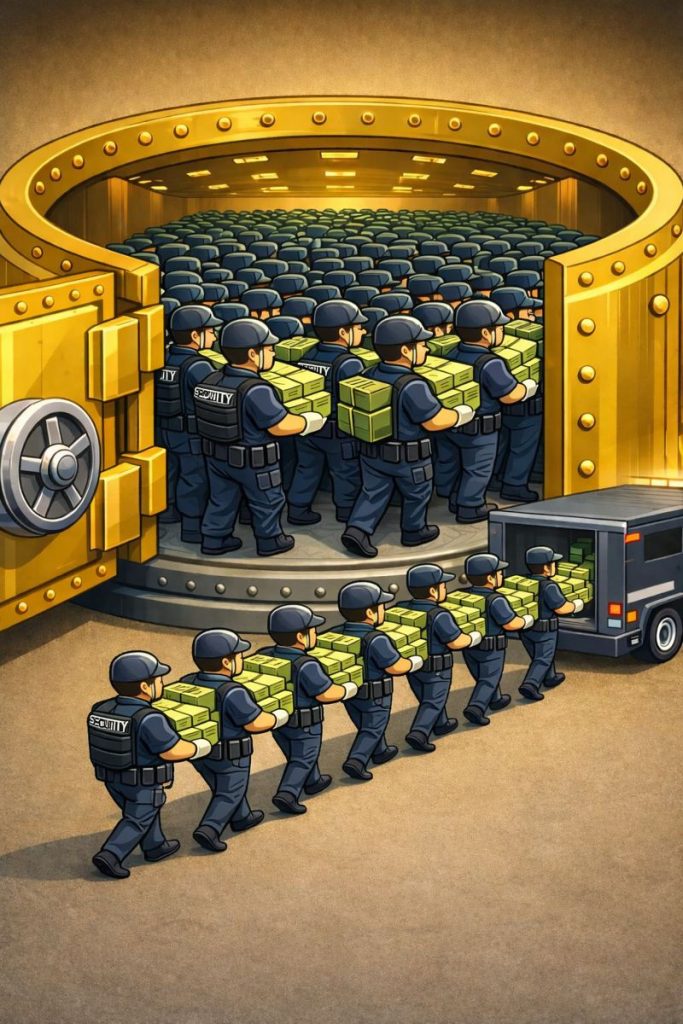

You can think of a battery as a vault.

For example, consider a 48V 100Ah lithium battery. Its total energy is 4,800Wh, which we can imagine as a vault containing 4,800 gold bars. The process of delivering electrical energy is equivalent to transporting gold bars out of the vault.

- Current (I), measured in amperes (A), describes how many people are carrying gold bars out of the vault per unit time.

- Voltage (U), measured in volts (V), represents how many gold bars each person can carry per trip. It describes each person’s carrying capacity.

- Power (W) describes how many gold bars can be transported per unit time.

(W = U × I)

When this battery is discharged at 48V and 5A, it can operate for 20 hours:

A group of people, each capable of carrying 48 gold bars per trip, leaves the vault at a rate of 5 people per hour. After 20 hours, all the gold bars are transported out.

When the same battery is discharged at 48V and 10A, it can operate for 10 hours:

The same group of people, each still carrying 48 gold bars per trip, now leaves the vault at a rate of 10 people per hour, and all the gold bars are transported out in 10 hours.

Similarly, when the voltage (each person’s carrying capacity) changes, the situation also changes.

If we switch to people with lower carrying capacity—for example, a voltage of 24V, where each person can carry only 24 gold bars per trip—and still send 10 people per hour, it will take 20 hours to transport all the gold bars out of the vault.

The total capacity (energy) of a battery is equal to:

Voltage × Current × Time (U × I × t)

This expression can be rearranged in different ways, each corresponding to a clear physical meaning.

When written as (U × I) × t, it becomes power multiplied by time (W × t).

This describes how long the battery can continuously supply energy at a given power level.

When written as (I × t) × U, it becomes ampere-hours multiplied by voltage (Ah × U).

When voltage is constant, a higher current will deplete the battery faster.

(When each person’s carrying capacity is fixed, sending more people out per unit time will result in all the gold bars being transported out more quickly.)

Is the Ah Rating of the Same Battery Fixed?

The short answer is: not necessarily.

In practice, even batteries that appear to be identical may have different ampere-hour (Ah) ratings listed on their datasheets by different manufacturers. The key reason is that Ah is not measured under isolated conditions. Instead, it is directly influenced by the discharge current used during the test.

How Discharge Current Affects Ah Measurement

By definition, Ah is the product of current and time. This means that the discharge current selected for testing has a direct impact on the measured capacity result.

When a battery is discharged at a lower, more moderate current, it can usually release more of its stored charge before reaching the cutoff voltage, resulting in a higher measured ampere-hour (Ah) capacity.

In contrast, when the same battery is discharged at a higher current, internal resistance and voltage drop increase, causing the cutoff voltage to be reached earlier. As a result, the usable discharge time is shorter and the measured Ah capacity is typically lower.

This is why battery capacity ratings are always tied to a specified discharge current or test condition.

This effect exists across all battery chemistries. However, the degree of impact varies significantly depending on the battery technology.

Ah Ratings on Datasheets: Lithium Batteries vs. Lead-Acid Batteries

For lithium batteries, the difference in measured Ah under different discharge currents is usually relatively small. Lithium-based electrochemical systems feature low internal resistance and fast reaction kinetics, allowing most of the stored charge to be released even at higher discharge rates. As a result, in real-world applications, the actual runtime delivered by lithium batteries is typically very close to the nominal Ah value stated on the datasheet.

For lead-acid batteries, the situation is fundamentally different. Due to higher internal resistance and slower electrochemical reaction rates, the measured Ah capacity decreases significantly as the discharge current increases.

This is why the lead-acid battery industry has long followed a specific convention:

Ah capacity is typically rated under a 20-hour discharge rate (C20)—that is, the battery is discharged evenly over 20 hours using a low, constant current.

While this method provides a standardized reference for capacity comparison, it also explains why, in real applications—where discharge currents are much higher than the C20 test condition—lead-acid batteries often fail to deliver their “rated” capacity.

This is also why users typically experience more predictable and accurate runtime performance with lithium batteries, whereas lead-acid batteries frequently fall short of their advertised or labeled capacity in practical use.

What Buyers Should Pay Attention To

Because the Ah value depends on specific test conditions, a single Ah number alone is not sufficient for proper evaluation.

When assessing or comparing different batteries, buyers should always confirm whether the datasheet clearly specifies the following information:

- The discharge current or C-rate used for Ah testing

- The cutoff voltage

- The test temperature

If this information is missing, it is advisable to confirm the exact test conditions with the manufacturer before making a purchase. Without this context, nominal Ah values can be misleading—especially when comparing different battery technologies.

Key Takeaway

Ah is not a single, absolute, and unchanging value—it is a result measured under specific conditions.

Understanding those test conditions is essential for accurately predicting how a battery will perform in real-world applications.

What Is Discharge Rate, and Why Is It Important When Selecting a Battery?

Once you understand how ampere-hours (Ah) are measured, the concept of discharge rate becomes much easier to grasp.

What Is Discharge Rate?

Discharge rate is commonly expressed as C-rate, which describes how fast a battery is discharged relative to its rated capacity.

Simply put, the C-rate indicates how quickly the stored charge in a battery is being consumed.

For example, for a 100Ah battery:

- 2Cmeans a discharge current of 20A, with a theoretical operating time of about 5 hours

- 5Cmeans 50A, with a theoretical operating time of about 2 hours

- 1Cmeans 100A, with a theoretical operating time of about 1 hour

- 2Cmeans 200A, with a theoretical operating time of about 30 minutes

The higher the discharge rate, the faster the stored charge in the battery is consumed.

Even when two batteries share the same nominal specifications—such as 48V 105Ah LiFePO₄—their real-world discharge capability can still be very different. This difference usually has little to do with the number printed on the label, and much more to do with how the battery is built internally.

Some batteries are designed around energy-oriented cells, optimized for longer runtime under moderate loads, while others use power-oriented cells that are better suited for delivering high current. On top of that, the maximum continuous and peak discharge capability of the cells, the current limits set by the BMS, and the way protection strategies are implemented all play a role in how much power the battery can actually deliver. Factors such as internal resistance, voltage stability under load, and even the design of the busbars and thermal management system further influence how the battery behaves when current demand rises.

Because of these differences, two batteries with the same voltage and Ah rating can perform very differently in the same application. One may deliver stable power throughout the operating cycle, while the other may struggle to supply the required current, show noticeable voltage sag, trigger protection mechanisms earlier than expected, or provide a much shorter runtime in practice.

This is why discharge rate must be considered alongside capacity when selecting a battery. Ah or Wh tells you how long a system could run under ideal conditions, but discharge capability determines whether the battery can reliably support the actual load profile of the application. In power-demanding systems such as electric vehicles, golf carts, forklifts, and industrial equipment, ignoring discharge rate often leads to batteries that look correct on paper, but fail to perform as expected in real use.

Only when both capacity and discharge capability are properly matched to the application can a battery deliver stable performance, operational safety, and the service life users expect.

Same Ah, Different Voltage — Why Higher Voltage Usually Means Longer Runtime

We now know that ampere-hours (Ah) represent the amount of charge stored in a battery. However, when two batteries have the same Ah rating but different voltages, their actual runtime can differ dramatically.

The reason is simple: energy depends on voltage.

A Practical Example: Powering the Same 12V Device with a 12V 100Ah Battery and a 48V 100Ah Battery

First, compare total stored energy:

- 12V 100Ah → Energy = 12 × 100 = 1,200Wh

- 48V 100Ah → Energy = 48 × 100 = 4,800Wh

Even though both batteries are rated at 100Ah, the 48V battery stores four times more total energy than the 12V battery.

Now assume we use a DC–DC converter (step-down converter) to power the same 12V load. Assume a practical conversion efficiency of 90% (actual efficiency depends on the converter and load, but 90% is a reasonable example).

The usable energy at 12V output becomes:

- 12V 100Ah battery (no conversion required): approximately 1,200Wh

- 48V 100Ah battery through a DC–DC converter at 90% efficiency:

4,800Wh × 0.90 = 4,320Wh

Now consider a typical 12V load. For example, a device consuming:

12V × 20A = 240W

The estimated runtime is:

- 12V 100Ah battery:

1,200Wh ÷ 240W ≈ 0 hours - 48V 100Ah battery (after conversion):

4,320Wh ÷ 240W ≈ 0 hours

In this example, the 48V 100Ah battery can power the same 12V device for approximately 18 hours, while the 12V battery can only supply about 5 hours of runtime.

The primary reason is that the 48V 100Ah battery starts with a much higher total energy content—even after accounting for conversion losses.

Key Point

Stepping down from 48V to 12V does not “create” additional capacity.

It simply allows you to utilize the much larger amount of energy stored in the 48V 100Ah battery to power a 12V device.

What Happens If You Choose the Wrong One

Selecting the appropriate battery Ah rating is not just about how long a system can operate. In real-world applications, it also determines whether the system can operate reliably—and in some cases, it can even affect safety.

Lithium batteries rely on a Battery Management System (BMS) to operate within defined voltage, current, and temperature limits. As long as the battery remains within these boundaries, energy output is stable and predictable.

Lead-acid batteries, on the other hand, are constrained by slower chemical reaction rates, rapid voltage drop under load, and external low-voltage protection built into controllers. As a result, the amount of energy that can actually be utilized from a lead-acid battery varies much more in practice, making real-world runtime far less predictable.

Why the Difference Becomes Critical Under Demanding Operating Conditions

This difference becomes especially pronounced under high-demand conditions.

In scenarios such as hill climbing, heavy-load operation, or low-speed high-torque work, motor current demand can increase sharply. If the selected Ah capacity is too small, the battery itself—or its protection system—may be unable to deliver the required current. When this happens, the system may lose power or shut down unexpectedly.

In lead-acid systems, this typically manifests as a rapid voltage drop. The vehicle feels underpowered, struggles to continue moving, or gradually comes to a stop.

In lithium battery systems, the behavior is different. If current limits are exceeded, the BMS may intervene to protect the battery, resulting in a sudden interruption of output.

Why System-Level Design Matters

This is where system-level design becomes critically important.

If electronic braking, steering, or control systems are not properly isolated from the traction battery, an unexpected power interruption can pose a real safety risk. This is especially true for vehicles that rely heavily on electronically assisted systems, where mechanical braking alone may not be sufficient.Imagine if your golf cart battery suddenly went out while you were going uphill—wouldn’t that be terrifying?

For this reason, battery selection should never be based on Ah alone. It must also take into account:

- Continuous discharge current capability

- Peak discharge current capability

- In lithium battery systems, how the BMS protection strategy is designed

High-quality lithium battery systems typically implement multi-stage protection logic. When abnormal current is detected, the system does not immediately cut off power. Instead, it first applies current limiting or power derating. Only if unsafe conditions persist does it execute a complete shutdown.

This approach protects the battery while avoiding sudden power loss to critical vehicle systems.

A Critical Safety Consideration

If abnormal current conditions trigger an immediate hard cutoff, electronic braking systems may stop functioning entirely. In such cases, relying solely on mechanical braking may not be sufficient to ensure safety.