- home

- golf cart battery

Golf Cart Battery

New Power Begins with Safety. Robur Never Rests.

See How We Guarantee the Quality of Your Golf Cart Batteries

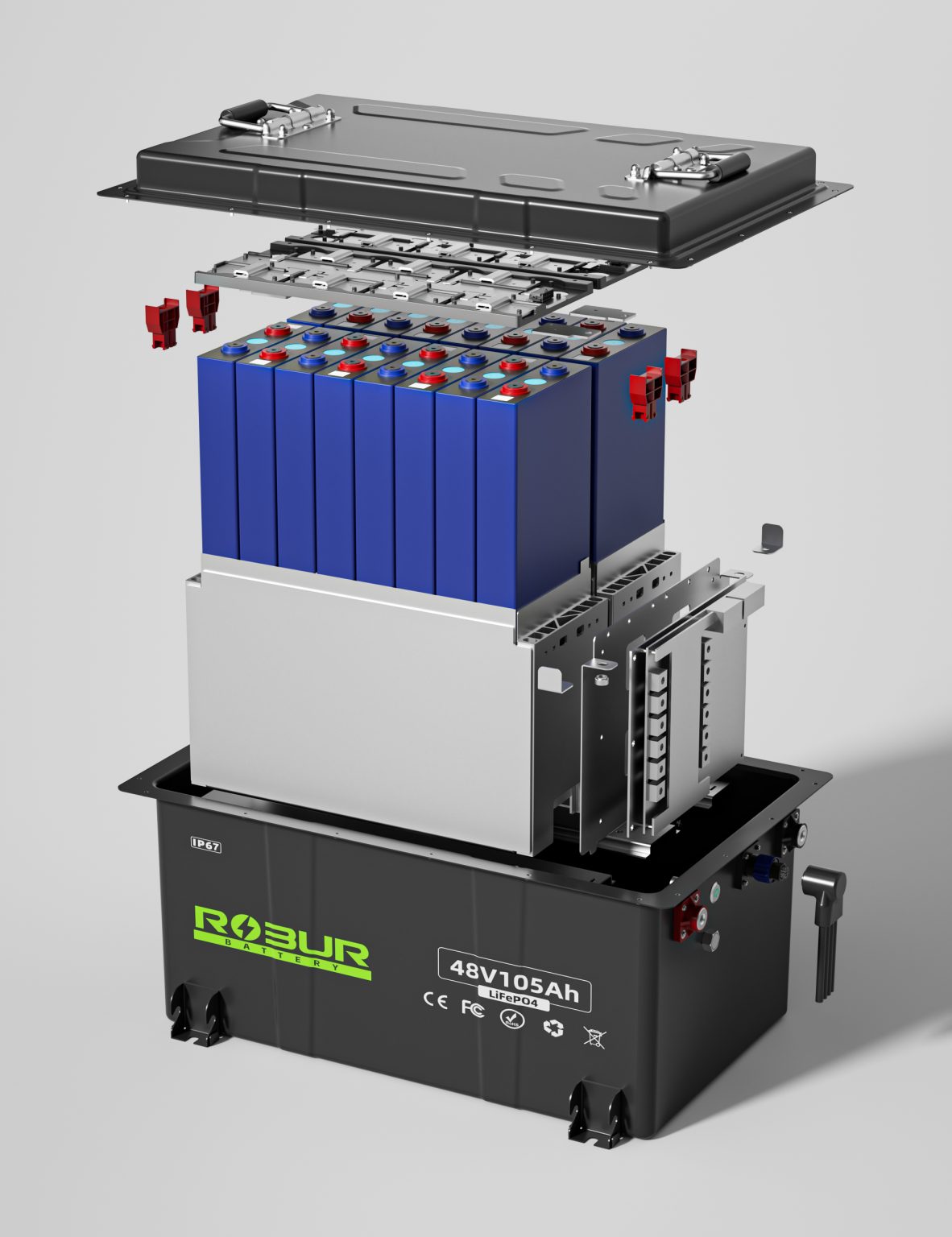

High-performance LiFePO₄ Golf Cart Battery Modules

Cell-to-Cell Fire-Resistance Barrier for Maximum Safety

High-stability aluminum profile frame

Precision Compression System for Longer Cycle Life

Automotive-Grade FPC Sensing and Laser-Welded Busbar System

System-Level Consistency for Long-Term Reliability

“

We Source A-Grade, Brand-New Cells from Top-Tier Suppliers — Fully Traceable from Origin For Our Golf Cart Battery.

Custom Golf Cart Lithium Battery Solutions

Golf cart performance and reliability rely on a stable, high-quality power system.

With Robur’s engineered lithium solutions, golf courses, fleet operators, and OEM manufacturers benefit from longer driving range, faster charging, higher efficiency, and a more dependable power platform designed for long-term performance and lower total operating cost.

Golf Cart Lithium Battery Customization Options

- Voltage & Capacity: 36V, 48V, 72V golf cart lithium battery systems, or bespoke configurations to match different models.

- Battery Enclosure: Custom casing dimensions and materials to fit golf cart compartments seamlessly.

- BMS Functions: Intelligent protection and communication protocols for safe and efficient operation.

- Charging Solutions: Standard and fast-charging options to reduce downtime and maximize fleet availability.

- Branding: Private labeling and OEM/ODM support for golf cart manufacturers and fleet managers.

With Robur’s golf cart lithium batteries, you not only upgrade vehicle performance but also reduce lifetime operating costs. Whether you operate a golf course fleet, run a rental business, or design new cart models, our lithium solutions deliver the efficiency, safety, and reliability your business needs.

Top Golf Cart Lithium Battery Manufacturer in China

Founded in 2006,Robur (brand owned by Dongguan Xintu Power Technology Co., Ltd.) is a genuine battery source manufacturer, it initially focused on the production and manufacturing of golf cart batteries. After more than a decade of development, it has now become a trusted brand in the field of lithium battery power solutions.

Through continuous expansion and relocation, we now operate with more than 500 employees and 30 automated production lines, reaching an annual capacity of 100,000 lithium batteries. Today, our products are trusted by customers in over 100 countries worldwide.

What makes us most proud is our people—over 100 of our employees have been with us for more than 10 years, reflecting our strong company culture and stability. Looking ahead, we remain dedicated to becoming the world’s most trusted manufacturer of golf cart lithium batteries.

Manufacturing Premium Golf Cart Lithium Batteries to the Highest Industry Standards

What Golf Cart Lithium Battery We Can Offer You

Didn't Find The Battery Parameters Suit You?Dodn't Worry!

Professional Golf Cart Battery Manufacturer

Robur is a dedicated golf cart lithium battery manufacturer delivering modules built with A-grade cells from top-tier suppliers. Designed with automotive-grade engineering, our batteries provide superior durability, stable power output, and long-term reliability for fleets and OEMs.

Why Robur Lithium Modules Outperform Standard Lithium Batteries

-

Module StructureSimple steel box; EVA spacers; no compression; wiring harness; low vibration resistance.Automotive-grade aluminum compression frame, laser-welded busbars, and robust structural rigidity. Designed for industrial vibration and long-term durability.

Many standard lithium packs are simply cells placed in a sheet-metal box with foam spacers and basic wiring. Robur modules are built on a true automotive-grade structure with an aluminum compression frame, rigid side profiles, and laser-welded busbars. This engineered design withstands vibration, shock, and long-term mechanical stress in demanding golf cart fleets.

-

Power Output PerformanceThin busbars or bolt connections; limited continuous discharge; heat buildup under load.High-current busbar system + low-impedance design. Stable performance for golf carts even under peak torque conditions.

Standard lithium packs often rely on thin busbars or bolt terminals, which limit continuous current and generate heat under heavy load. Robur modules adopt a low-impedance current path with wide busbars and optimized connections, enabling stable high current output for acceleration, hills, and heavy-duty use. Golf carts equipped with Robur batteries maintain stronger torque and more consistent power delivery throughout the discharge.

-

Safety & Sampling SystemBasic BMS; wire harness voltage sensing prone to loosening or EMI interference.Automotive FPC sensing, precise cell-level monitoring, and multi-layer safety architecture (compression + aluminum housing + industrial BMS).

In many generic packs, cell voltages are measured through loose wire harnesses and basic BMS designs, increasing the risk of inaccurate readings and undetected faults. Robur uses automotive FPC flexible circuits for precise cell-level sampling, combined with multi-layer protection logic in our industrial BMS. This ensures accurate monitoring, faster fault response, and a much higher overall safety margin for operators and fleets.

-

Thermal PerformanceNo thermal engineering; hotspot issues; uneven cell aging.Aluminum housing & cell compression create uniform heat distribution → longer lifespan and stable performance in all climates.

Poorly engineered lithium packs can suffer from hotspots and uneven cell temperatures, which accelerate aging and reduce capacity. Robur’s aluminum housing and compression structure create an efficient heat path, keeping cells at a more uniform temperature during charging and discharging. The result is better performance in both hot and cold climates, and more stable operation over the full life of the battery.

-

Durability & Cycle Life1500–2500 cycles (varies heavily by supplier).3000–6000+ real industrial cycles using A-grade cells and engineered module design.

Because of mixed cell sources, weak structures, and limited thermal control, many standard lithium batteries start to lose capacity quickly after a few hundred cycles. Robur combines A-grade cells with automotive-grade module engineering to achieve 3,000–6,000+ real cycles in golf cart duty. For fleet owners, this means fewer replacements, less downtime, and a much longer effective service life per pack.

Unlike typical lithium batteries assembled with mixed cells and basic structures, Robur designs and manufactures true automotive-grade lithium modules specifically for golf cart applications. Our modules use A-grade cells from top-tier suppliers, combined with a high-rigidity aluminum frame, laser-welded busbars, and FPC precision sensing. This engineered architecture ensures superior current capability, thermal management, vibration resistance, and long-term reliability for fleet operators and golf course users.

Golf Course Fleets → Significantly higher reliability, longer runtime, and reduced maintenance downtime.

Rental Companies → Robust modules withstand daily cycling, frequent charging, and harsh operation.

OEM Manufacturers → True automotive-grade module design enables higher performance and longer warranty cycles.

With Robur’s automotive-grade golf cart lithium modules, you don’t just upgrade the battery — you upgrade the entire power system. Our A-grade cells, engineered module structure, and industrial-level reliability give your fleet longer life, safer operation, and higher value over time.

How to Work With Us

Step 1. Define Requirements

Tell us about your application scenario — voltage, capacity, dimensions, operating environment, and any special needs.

Step 2. Engineering Evaluation

Our engineering team reviews your requirements and proposes the best custom battery pack solution, including BMS integration and safety considerations.

Step 3. Sample Development

Tell us about your application scenario — voltage, capacity, dimensions, operating environment, and any special needs.

Step 4. Customer Testing & Feedback

You run performance and compatibility tests in real-world conditions. Our team works with you to optimize design details if adjustments are needed.

Step 5. Mass Production & Delivery

After sample approval, we move to full-scale production. Each battery pack passes rigorous quality inspections before secure packaging and on-time delivery.